|

A university

professor uses Saber Designer to help Ford Motor Company and his

students gain new perspectives on the engineering design process. At

Ford, his simulations identified the previously overlooked wire harness

as having a significant impact on overall system performance. Using

Saber, Dr. Ash discovered that the wiring harness significantly impacted

overall system performance, a fact that went undetected by traditional

subsystem simulations.

I believe

that this is the first automotive design effort that models the total

vehicle system by using mostly generic device models from the Analogy

library.

Dr. Armand

Ash-Rafzadeh

Total Vehicle Electric Design

Automation (EDA)

System Engineering Approach

Most of us take our cars for granted. We

open the door, adjust the seat and turn the key in the ignition. The

engine fires up and we pull out into the street. All the vehicle

electronics - the power door locks, the seat positioner, the ignition

controls, the anti-lock braking system, even the headlights and radio —

work as expected. But designing all these individual subsystems to work

in perfect harmony is a tremendously complicated challenge for

automotive engineering teams.

Faced with the rapidly increasing

complexity of its electrical subsystems, Ford Motor Company called on

noted professor and consultant Dr. Armand Ash-Rafzadeh (“Dr. Ash”) to

develop an improved design process. The goal was to expand Ford’s design

awareness so they could manage the performance of systems as a whole —

not just the individual performance of subsystems. Ford’s prevailing

design program focused on subsystems, rather than total system and

connectivity between subsystems. “The old methods didn’t take the wire

harness into account. Design and testing were fragmented,” said Ash. The

individual systems were separately designed, simulated, prototyped, and

modified. This caused problems with simulation because there was no way

to account for the interconnections between the vehicle subsystems. Ash

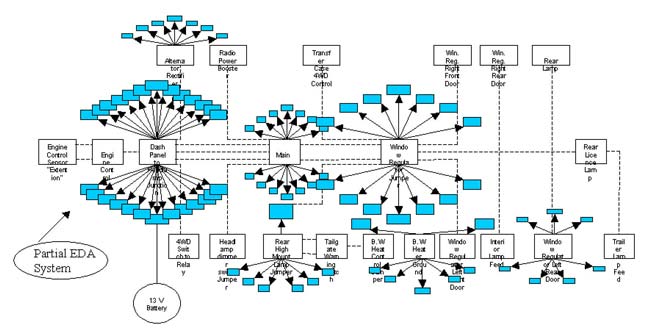

faced this challenge by developing a new design process he called the

“Wire Harness Centric View” (WHCV). This new methodology isolates each

wire harness rather than each subsystem. Thus, the design perspective

becomes essentially that of a wire harness connected to all of its

components. To simulate the complex interactions of these linked

systems, Dr. Ash turned to Analogy’s Saber Designer.

“We put the system together and were very

successful,” said Ash. “I believe that this is the first automotive

design effort that models the total vehicle system by using mostly

generic device models from the Analogy library.” Using WHCV helped

identify the crucial circuit modifications needed, and it did so very

early in the design cycle.

Ash’s consulting firm, Mechatronics, Inc.,

placed eight Saber-trained employees as subcontractors to Ford. Using

the lessons learned from the WHCV program, Ash began specifying the

device models needed for a Total Vehicle Analysis. The first step was to

apply Ash’s newly- created Vehicle Element Identification Process (VEIP).

VEIP was used to develop a list of “commodities” – components in the

vehicle that were to be simulated — and a complete specification of the

simulation model. In addition to generating the requirements for

Analogy’s MAST® modeling, VEIP also simplified data management and the

creation of schematic symbols.

Ash began by using Saber and his new

process to analyze a complete steering system. The process used vehicle

sensor data, the digital signal processing capabilities of MATLAB®, and

the system and mechatronic simulation capabilities of Saber and MAST.

The objective was to identify the source of noise that occurred at low

speeds and disrupted the steering-fluid flow rate. Results from the

Saber simulation allowed designers to modify the control circuit to

maintain the proper fluid levels. On subsequent projects, Ash and his

team made full use of Saber’s capabilities. “We used everything [in

Saber] that there was,” said Ash. “Monte Carlo was most helpful. We

evaluated the negative performance impacts that came from the

interaction of component tolerances. We also quantified the contribution

of each component or component cluster.” Ash also used Monte Carlo

analysis to study how component combinations can affect subsystem

performance. “We can measure performance levels and buy the appropriate

quality of components needed by that particular subsystem.” “My ultimate

goal is to get as many companies involved in the VEIP process as

possible,” said Ash. “We’d like to provide this solution to other

companies in the industry. Ford is fanatical about this. They realize

that this is a very important strategic tool for automotive design. It

doesn’t only perform systems analysis; it changes the whole design

culture. It gets you involved in data management, data structures, and

many other processes. The automotive industry knows the importance of

this, but few companies have made the necessary commitment to change. It

hasn’t yet been integrated into their engineering cultures.” Based on

his successes at Ford, Ash obtained Saber as a teaching tool for his

classes at the University of Detroit. He identified promising graduate

students and brought them into his projects.

S A B E R S U C C E S S E S

“Using Saber helps my students become

really ingenious. It brings out the ‘real’ engineer in them and lets

them apply their skills with greater creativity and effectiveness. Those

who become proficient with Saber really gain a higher-level

understanding of the systems they work with.” |