|

Home

»

Mechatronics

»

Mechatronics

Products

»

High Power Electrical

Systems |

|

|

|

High Power Electrical

Systems

|

|

This product is a highly

integrated Mechatronics product consisting of mechanical, electromagnetic, and

electromechanical components and subsystems of a car modeled based on 42V

technology. The product enables users to perform simulation, and analysis of

components and subsystems of a dual voltage system.

Note: Generic products with similar functionalities are available on the

market for up to 100k per copy. This product is, however, much more specific

compared to generic products and when 42v becomes the auto industry standard; it

has the potential of becoming Mechatronics Inc. number one product.

Using MAST, Saber Simulation Environment modeling language, models for all

components used in the dual-voltage system are developed, e.g., the

alternator, batteries, DC/DC converter, and loads. By simulating the system,

the flow of power through the system was monitored as the power supply and

demand changes with vehicle speed changes (drive-cycle) and load on-off

transitions (load-cycle). The simulation results, and in particular, the

final battery state of charge at the end of each transient analysis, were

then used to make judgments regarding the sizing of the power supply

components

The basic dual-voltage system consists of two buses; one supplied by the

existing standard 12V battery and regulated at 14V, and the other supplied

by a 36V battery and regulated at 42V. All high-power loads are located on

the 42V bus. All low-power loads are placed on the 14V bus. Two scenarios

have been analyzed; dual/single alternator systems.

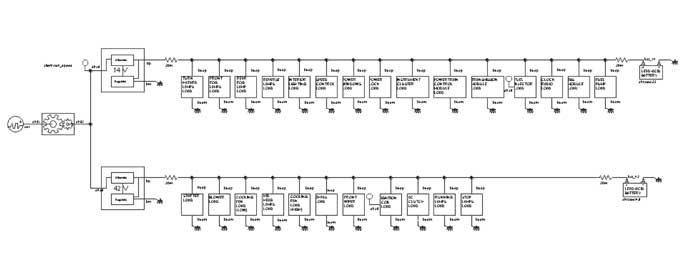

• Dual Alternator System; is based on two alternators providing both high

(42V) and low (14V) voltage outputs.

|

|

|

Figure 1

Saber design of dual alternator system |

|

|

|

•

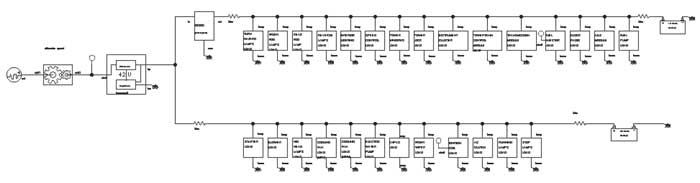

Single Alternator System; is

based on one alternator providing high (42V) voltage output. The lower

voltage (14V) is derived from the high voltage bus by use of a dc/dc

converter. |

|

|

|

|

Figure 2 Saber design of single alternator system with DC/DC converter |

|

|

|

List of loads modeled in

the product are as follows. |

|

42 Volts Loads |

14 Volts Loads |

Small Loads |

|

StarterFuel

Pump

Blower Motor

HID Headlamps

Cooling Fan

Electric Water Pump

EHPAS Motor

Front Motor Wiper

Ignition Coils |

AC Clutch

Interior Lighting

Front Fog Lamps (Bulb)

Rear Fog Lamps (LED)

Running Lamps (LED)

Stop Lamps (LED)

Turn/Hazard Lamps (LED)

Reversing Lamps (Bulb) |

Speed Control

(Electronic Throttle)

Power Windows

Power Locks

Instrument Cluster

Powertrain Control Module

Transmission Module

Fuel Injectors

Clock/Radio

ABS Module |

|

|

|

|

To evaluate the power flow in

the dual-voltage system, the system’s supply and demand of power under

typical driving conditions needed to be simulated. This required the use of

two types of data: drive-cycles or engine speed profile and load-cycles. The

length of the engine speed profile used is 800 seconds. A number

of standard and non-standard drive-cycles exist and are used in the industry.

Table 1 lists each drive-cycle used in this product and a brief

description of each. |

|

|

|

Table 1

Drive-cycles used in simulations |

|

Drive-cycle |

Description |

|

(CLCC -

summer) City Load Carrying Capacity |

Simulates low

speed city driving in summer |

|

(CLCC -

winter) City Load Carrying Capacity |

Simulates low

speed city driving in winter |

|

(IDLE -

summer) Engine Idle Cycle |

Simulates

stopped or slow traffic in summer |

|

(IDLE -

winter) Engine Idle Cycle |

Simulates

stopped or slow traffic in winter |

|

(CNL) Country

Night Load |

Simulates

highway driving |

|

|

|

|

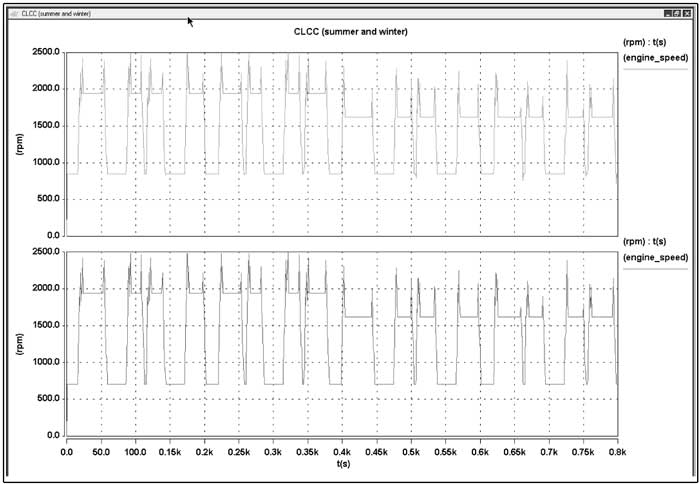

Figure 3 below shows two

typical drive-cycles (CLCC summer and winter, respectively), the engine

speed in revolutions per minute plotted against time in seconds. Engine idle

speed is 850 rpm for summer and 700 rpm for winter. Engine speed for Country

Night Load (CNL) is 2752 rpm. |

|

|

|

|

Figure 3

City Load Carrying Capacity engine speed profiles used in dual alternator

system (in summer and winter) |

|

|

|

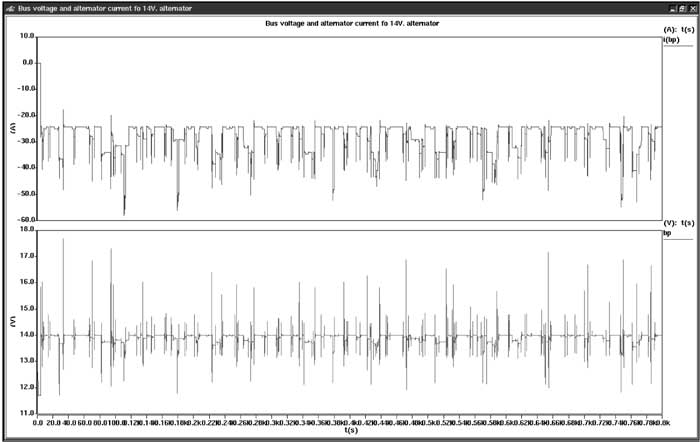

Besides specifying the car’s

speed, which determines the amount of power that can be supplied to the

system by the alternator, it is also necessary to specify the sequence of

load events, which will demand power from the electrical system.

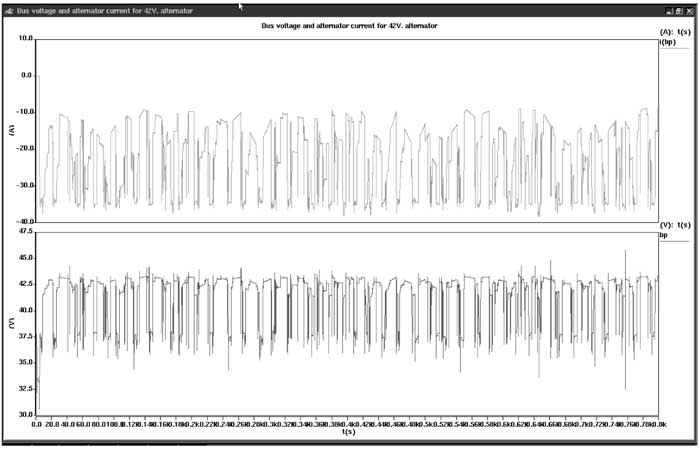

Figure 4 (14 volts) and Figure 5 (42 volts) show alternator currents and bus

voltages for CNL drive-cycle for the dual alternator system. |

|

|

|

|

Figure 4

(14 volts) bus voltage and alternator current for 14 volts alternator (CNL) |

|

|

|

|

Figure 5

(42 volts) bus voltage and alternator current for 42 volts alternator (CNL) |

|

|

|

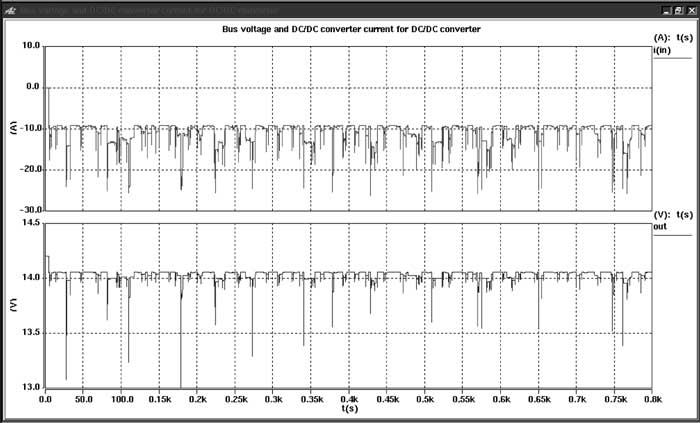

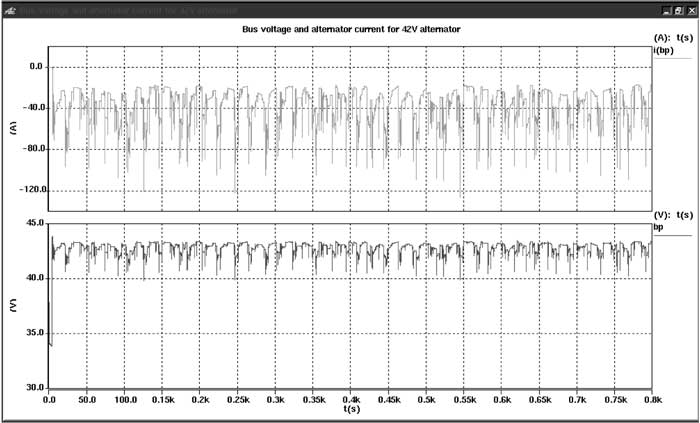

Figure 6 (14 volts) and

Figure 7 (42 volts) show DC/DC converter and alternator currents and bus

voltages for CNL drive-cycle for the single alternator system.

|

|

|

|

|

Figure 6 (14 volts) bus voltage and current for DC/DC converter (14 volts

side) (CNL) |

|

|

|

|

Figure 7 (42 volts) bus voltage and alternator current for 42 volts

alternator (CNL) |

|

|

|

If you need any information

about this Product please click

here and submit your query.

You will be contacted shortly

by one of our experts. |

|

Copyright © 1993-2005 Mechatronics Inc. All Rights Reserved |